Throughout history, the development of railway track material has played a crucial role in the advancement of transportation systems. From humble beginnings to sophisticated modern designs, the evolution of railway track material has been a fascinating journey.

In the early days of railways, wooden rails were commonly used. These rails were prone to wear and decay, requiring frequent maintenance and replacement. As the demand for railways increased, engineers began searching for more durable materials.

The next significant development came with the introduction of cast iron rails. Cast iron provided a more robust and longer-lasting alternative to wood. However, these rails were heavy and prone to breakage, limiting their usefulness in heavy traffic areas.

With the advent of the Industrial Revolution, the production of steel became more efficient and cost-effective. This breakthrough led to the adoption of steel rails in railway track construction. Steel rails offered superior strength, durability, and flexibility compared to their cast iron counterparts.

To further enhance the performance of steel rails, engineers introduced the concept of continuous welded rail (CWR). CWR eliminated the need for rail joints, which were susceptible to wear and required frequent maintenance. By welding the individual rail sections together, CWR provided a smoother and more stable ride for trains.

The development of CWR also led to the introduction of concrete sleepers. Concrete sleepers replaced traditional wooden sleepers, providing better support and stability for the rails. They were also more resistant to decay and required less maintenance, making them a popular choice for modern railway track construction.

In recent years, the focus has shifted towards innovative materials that offer even greater performance and sustainability. One such material is composite rail technology. Composites, such as fiberglass-reinforced polymer (FRP), offer a lightweight and corrosion-resistant alternative to traditional steel rails. These materials have the potential to reduce maintenance costs and increase the lifespan of railway tracks.

Another area of advancement is the development of smart railway track materials. These materials are embedded with sensors and data collection devices, allowing for real-time monitoring of track conditions. This technology enables proactive maintenance, reducing the risk of track failures and improving overall safety.

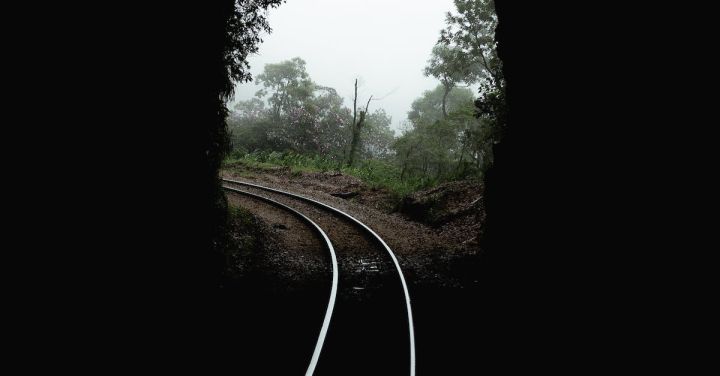

In addition to material advancements, the design and layout of railway tracks have also evolved. The introduction of high-speed rail systems has led to the development of tracks with smoother curves and gradients, allowing trains to travel at higher speeds safely. These designs incorporate advanced track geometry and alignment techniques to ensure optimal performance.

As we look to the future, the evolution of railway track material will continue to be driven by the need for increased efficiency, sustainability, and safety. Researchers are exploring the use of alternative materials, such as carbon fiber composites, that offer even greater strength and durability. Furthermore, advancements in 3D printing technology may revolutionize the manufacturing process, allowing for customized track components and faster production times.

In conclusion, the journey of railway track material has seen significant advancements over the years. From wooden rails to composite materials, the evolution has been driven by the need for improved performance and longevity. As technology continues to advance, we can expect further innovations that will shape the future of railway track construction.